Synchronous belt pulley 8MGT

What material is the synchronous belt pulley made of? Since the synchronous belt pulley is an important component, it is generally made of materials such as steel, aluminum, alloy cast iron, brass, etc. The final material selection may vary depending on the location of use. Of course, our component will also undergo some special treatments before use, such as natural oxidation, galvanizing, high-frequency quenching, and so on.

What are the characteristics of synchronous pulleys:

Its transmission performance is accurate, there will be no sliding during operation, and it has a certain transmission ratio. So the transmission system of synchronous pulleys is particularly stable and has a certain degree of buffering. Not only can it absorb shock, but the noise it generates is particularly low.

As is well known, the transmission efficiency of synchronous pulleys is relatively high, generally up to 0.98, so their energy-saving effect is also quite significant. Because it is easier to maintain in the factory and generally does not require lubrication, its cost is relatively low.

How to choose a synchronous pulley

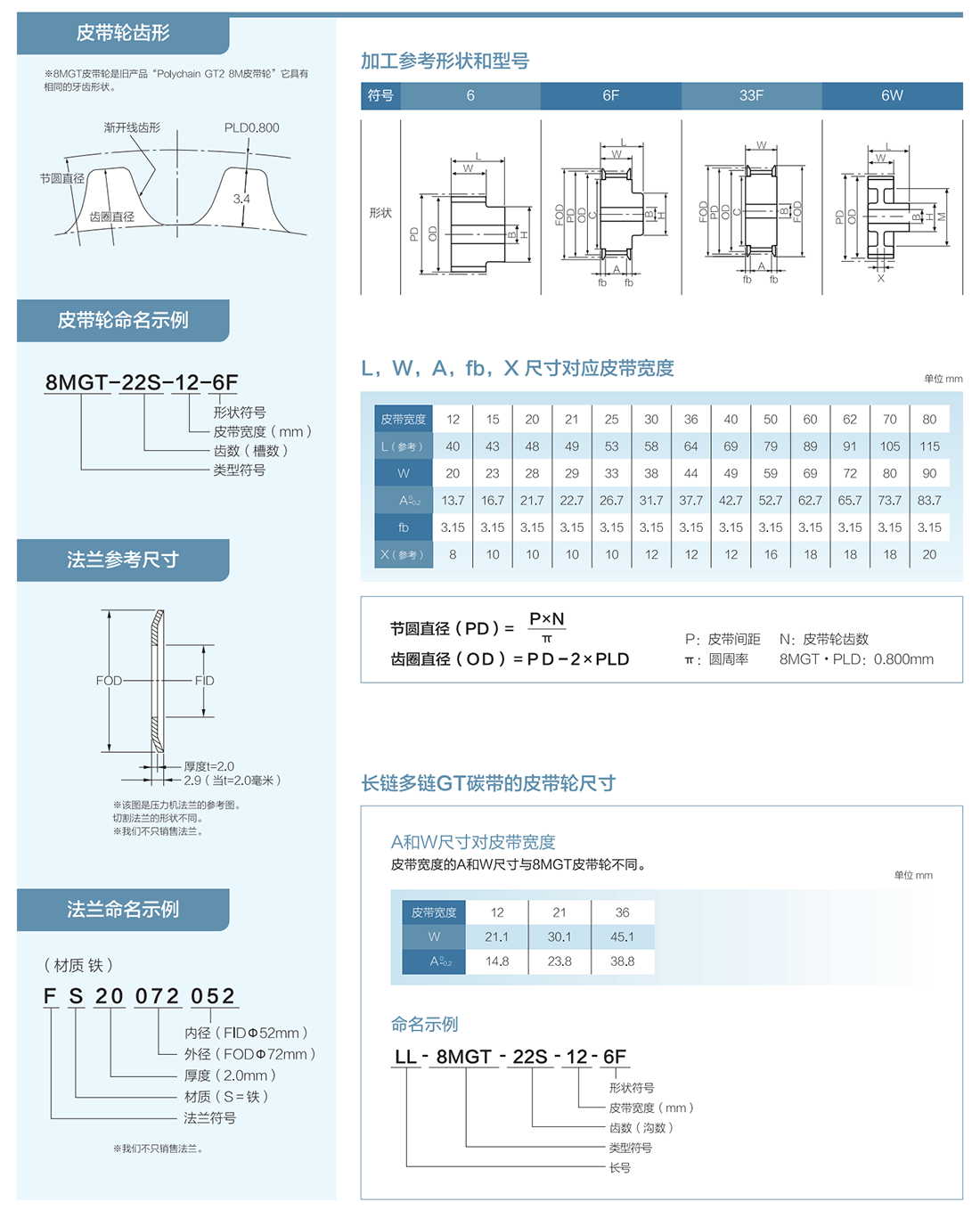

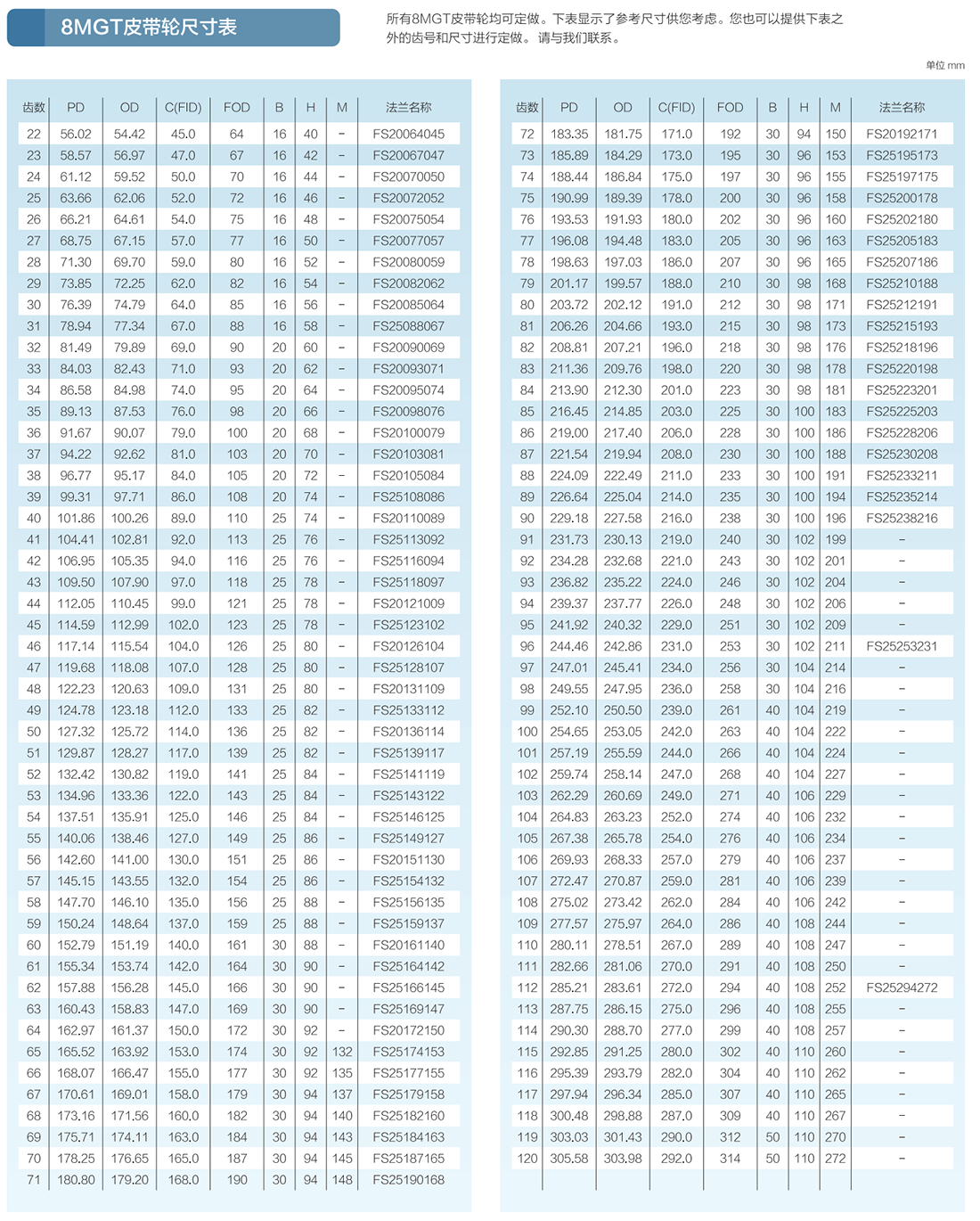

1. When selecting a model, the first step is to determine the required number of teeth, pitch diameter, and structure of the synchronous wheel product based on the tooth profile model of the synchronous belt and synchronous pulley, as well as the relevant meshing parameters such as the pitch of the synchronous belt and synchronous pulley.

2. The calculation of the number and diameter of synchronous teeth requires first determining the number of teeth on the small synchronous wheel, and then determining the number of teeth on the large synchronous wheel based on the transmission ratio of the synchronous wheel transmission system.

3. In order to ensure the service life of the synchronous wheel, the diameter of the small synchronous wheel should be smaller than the maximum allowable bending diameter of the synchronous wheel, and then the maximum number of teeth of the synchronous wheel should be calculated based on the data. If the structure and cost permit, and considering factors such as the service life of the synchronous belt, it is ideal for the number of small synchronous teeth to be slightly larger than the allowed minimum size.

4. When determining the number of teeth for the small synchronous wheel, the number of teeth for the large synchronous wheel is determined based on the transmission ratio of the synchronous wheel transmission system, and finally the center distance between the two synchronous wheels is determined based on the synchronous wheel transmission structure.

We chat