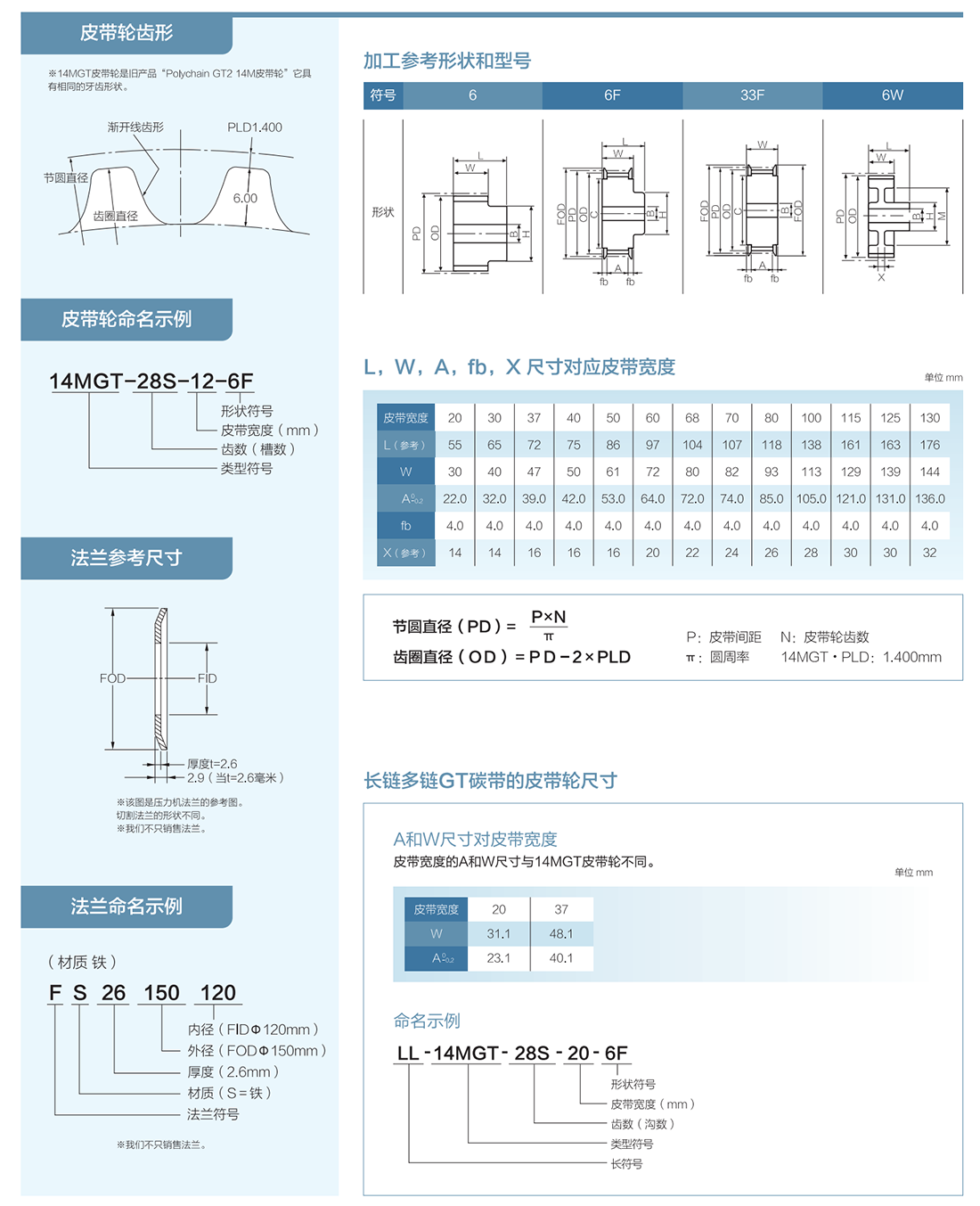

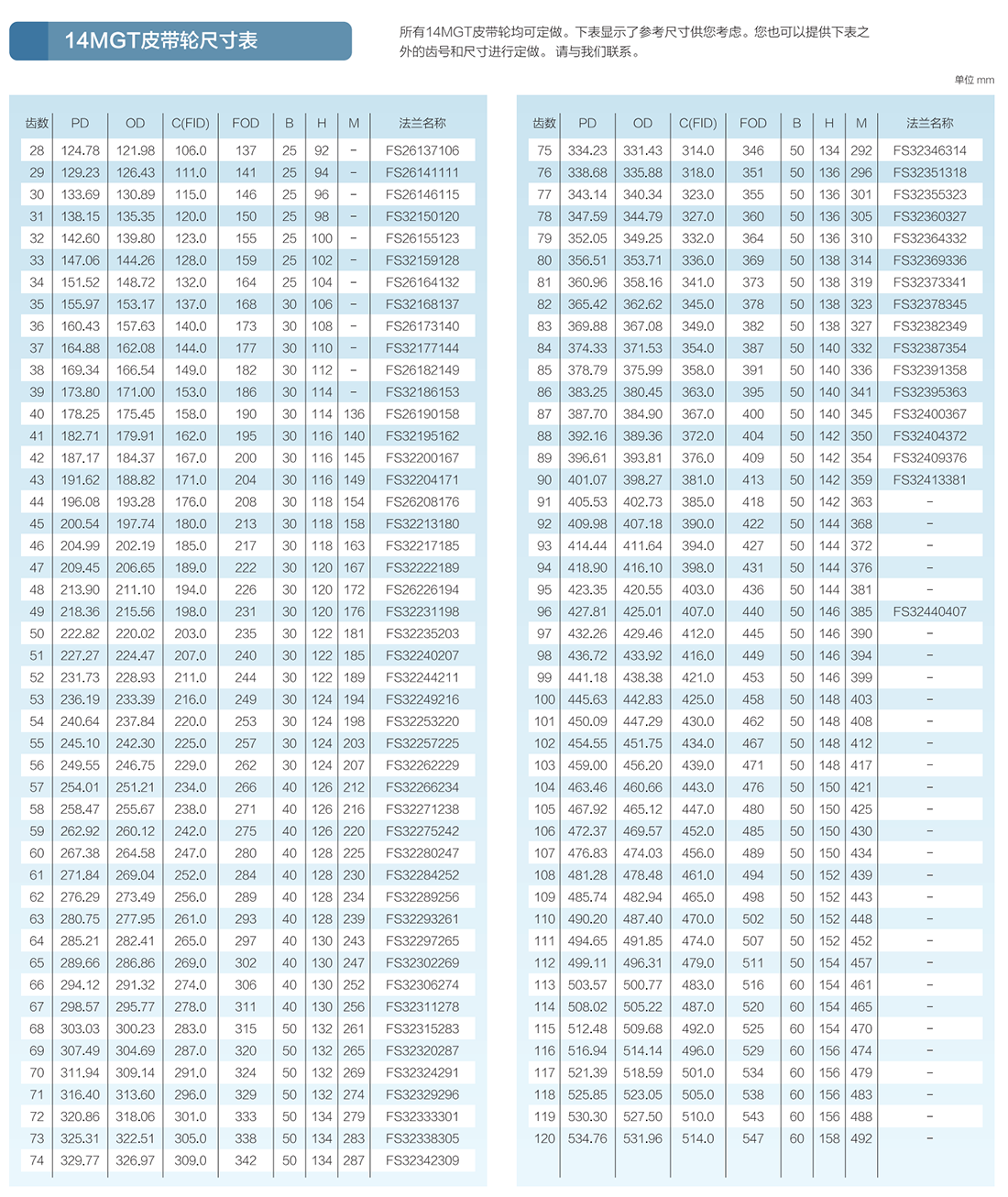

Synchronous belt pulley 14MGT

Synchronous belt pulley refers to a material generally made of steel, aluminum alloy, cast iron, brass, etc. Its inner hole has circular holes, D-shaped holes, conical holes, and other forms. Synchronous belt pulley transmission is composed of a closed circular tape with equidistant teeth on the inner surface and corresponding pulleys.

Surface treatment includes natural oxidation, blackening, galvanizing, color zinc plating, high-frequency quenching, and other treatments. The accuracy level depends on customer requirements.

Characteristics of synchronous belt pulley

1. Accurate transmission, no sliding during operation, with a constant transmission ratio; 2. Smooth transmission, with buffering and damping capabilities, and low noise; 3. High transmission efficiency, up to 0.98, with significant energy-saving effect; 4. Easy maintenance, no need for lubrication, and low maintenance costs; 5. The speed ratio range is large, generally up to 10, and the linear speed can reach 50m/s. It has a large power transmission range, ranging from a few watts to several hundred kilowatts; 6. Can be used for long-distance transmission, with a center distance of up to 10m or more; 7. No pollution, can work normally in places where pollution is not allowed and the working environment is relatively harsh.

Synchronous belt pulley steps

1. Simplified design: Determine the main parameters such as center distance and modulus based on the transmission power, input speed, transmission ratio, and other conditions of gear transmission. If the center distance and modulus are known, this step can be skipped.

2. Geometric design calculation: Design and calculate the basic parameters of gears, and perform geometric dimension calculations.

3. Strength verification: After determining the basic parameters, accurate verification of tooth surface contact strength and tooth root bending strength is carried out.

Advantages of synchronous belt pulley

Synchronous belts can be divided into chloroprene rubber and fiber rope synchronous belts, polyurethane and steel wire synchronous belts according to their materials. According to the shape of the teeth, they are mainly divided into two categories: trapezoidal teeth and circular arc teeth. According to the arrangement of the teeth, they can be further divided into single-sided toothed synchronous belts and double-sided toothed synchronous belts. Synchronous belt transmission has accurate transmission ratio, no slip, can obtain constant speed ratio, precise transmission, smooth transmission, shock absorption, low noise, wide transmission speed ratio range, generally up to 1:10, allowable linear speed can reach 50m/s, high transmission efficiency, generally up to 98% -99%. Transmitting power from a few watts to several hundred kilowatts. Compact structure and suitable for multi axis transmission, with low tension, no need for lubrication, and no pollution.

We chat